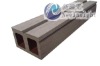

Product Name:Dragon Grand Wood

function:waterproof

color:8 main colors

Composition:wood /plastic

Usage: outdoor decking etc.

Dragon Grand Wood offers the best advantages of plastic and wood .theplastic shields the wood from moisture and insect damage .so there is no rotting or splintering.the wood protects the plastic from UV damage and gives you a natural feel .high strength and rigidity ,skdproof ,adrasion resistance ,inflammation resistance ,resists moisture ,insects and UV,insulation,heat insulation,resists from -40 low temperature to 60 high temperature .

A batter weather -resistant and (sea)water-resistant outdoor construction material ----Dragon Grand Wood ,is the optimum choice for all outdoor applications and installs more easily than traditional wood material .the surface looks great of its natural wood appearance with minimal maintance .

WPC engineered flooring --Beijing 2008 Olympic Project

Verified Information

This information is Verified by Bureau Veritas and validity period is

2012/09/27 --- 2013/09/27

All the information below may covers both Gold Supplier and its related companies , Their Relationship will be affirmed according to china laws and regulations , also it will be clearly display in the full report >>

Production Capacity:

Product line name

Production Line Capacity

Actual Units Produced(Previous Year)

| WPC |

USD11,250,000 per year |

USD6,913,328 |

Export Market Distribution:

Market

Revenue(Previous Year)

Total Revenue (%)

| North America |

USD 51,150 |

0.74 |

| South America |

USD 35,892 |

0.52 |

| Eastern Europe |

USD 221,100 |

3.2 |

| Southeast Asia |

USD 5,209 |

0.08 |

| Africa |

USD 89,148 |

1.29 |

| Oceania |

USD 365,147 |

5.28 |

| Mid East |

USD 169,332 |

2.45 |

| Eastern Asia |

USD 589,528 |

8.53 |

| Western Europe |

USD 2,724,962 |

39.41 |

| Central America |

USD 325,982 |

4.72 |

| Northern Europe |

USD 1,133,108 |

16.39 |

| Southern Europe |

USD 367,321 |

5.31 |

| South Asia |

USD 253,046 |

3.66 |

| Domestic Market |

USD 582,401 |

8.42 |

Production Machinery:

Machine Name

Brand & Model No.

Quantity

Number of Year(s) Used

Condition

| Drying machine |

No information |

1 |

3.1 |

Acceptable |

| Mixing machine |

SHR-800A |

5 |

3.0 |

Acceptable |

| Beards producing machine |

SHJ-72 |

5 |

3.2 |

Acceptable |

| Extruding machine |

SJZ-65/132 |

19 |

2.5 |

Acceptable |

| Cutting machine |

No information |

2 |

3.0 |

Acceptable |

| Sanding machine |

SR-G600 |

7 |

3.0 |

Acceptable |

Testing Machinery:

Machine Name

Brand & Model No.

Quantity

Number of Year(s) Used

Condition

| Electronic universal strength tester |

MWW-50 |

2 |

1.5 |

Acceptable |

| Impact tester |

XJJ-5 |

1 |

3.0 |

Acceptable |

| Drying stove |

101A-2 |

1 |

3.5 |

Acceptable |

| Moisture content tester |

Sh10A |

1 |

2.0 |

Acceptable |

| Electrical stove |

SRTX-2-9 |

1 |

3.5 |

Acceptable |

| Electronic scale |

No information |

1 |

3.0 |

Acceptable |

| Caliper |

No information |

20 |

1.0 |

Acceptable |

Production Flow:

1.Material drying

2.Material mixing

3.Beards producing

4.Extruding and cooling

5.Cutting

6.Sanding

7.Inspecting

8.Packing

Certification:

Certified Picture

Certification Name

Certified By

Certificate No.

Product Name & Model No.

Available Date-Expired Date

|

ISO9001:2008 |

WIT & ANAB |

15/10Q0080R00 |

Scope: Design, development and production of extruded wood plastic composite |

2010/02/04 --- 2013/02/03 |

|

ISO14001:2004 |

WIT & ANAB |

15/10E0081R00 |

Scope: Environmental Management Related to design, development and production of extruded wood plastic composite |

2010/02/04 --- 2013/02/03 |

|

FSC Certification |

Bureau Veritas |

BV-COC-019270 |

Scope: Manufacturing of Bamboo or Wood Plastic Composite Certified FSC 100% |

2012/03/30 --- 2017/03/29 |